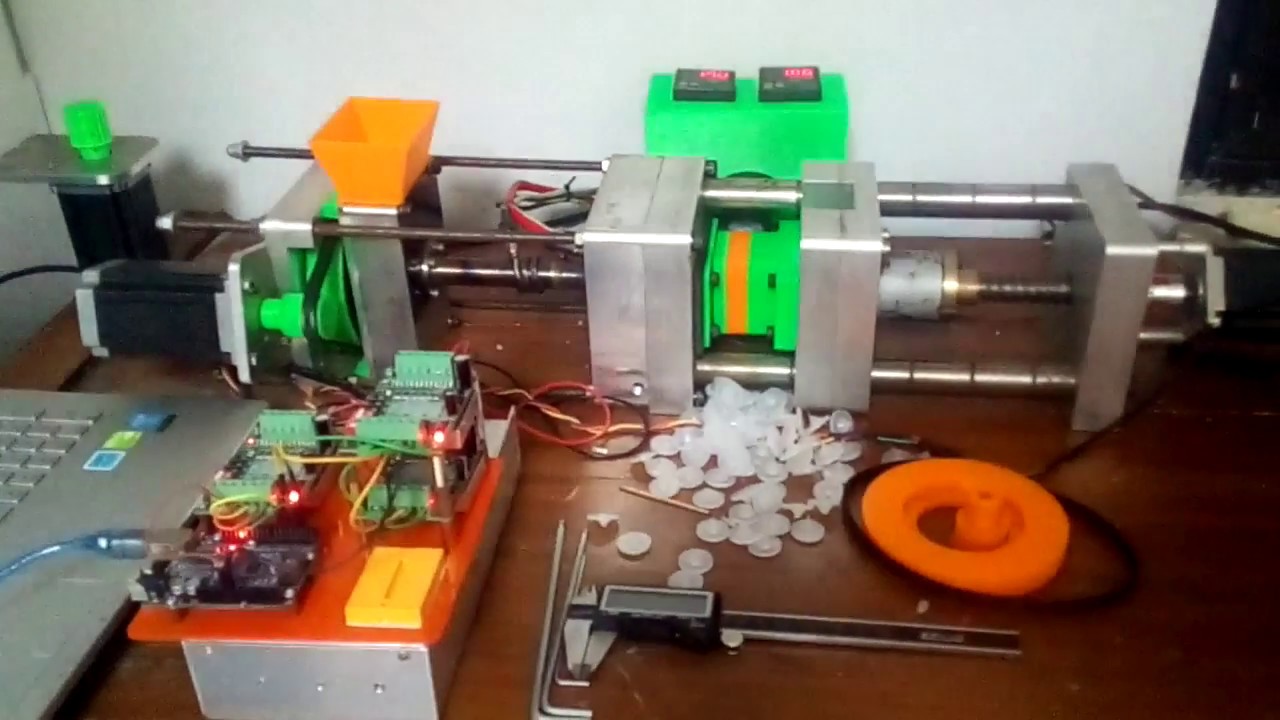

diy plastic injection molding machine

0217 2022 Industrial 40 Temperature and Humidity Enclosures. Medical Consumer Robotics Architecture Aerospace Gaming Drones Education Jewelry Materials.

Electronics Cars Fashion Collectibles Coupons And More Diy Molding Plastic Injection Molding Plastic Moulding

Although there are certain factors that can drive the cost of injection molding up or down if you begin with the right formula to calculate the cost per part you may be able to.

. We suggest the Model 150A from LNS Technologies. A port injection system which consisted of a fuel suction tube with pump and gauge assembly fuel pipe sub-assembly and fuel injector assembly. Purchase Automation Components and many other industrial components.

Detailed guidance regulations and rules. Sir we would just like to ask these following questions. Last Updated on March 8 2022.

The best way to figure out how much you can save with injection molding services over other manufacturing methods is to compute the cost per part. Gingery Publishing 1997 ISBN 1-878087-19-3. MJF Plastic PA12 Nylon 12 Glass Beads MJF Plastic PA12GB Polypropylene PP.

Departments agencies and public bodies. Learn how to do just about everything at eHow. The molding of plastic materials is the set of all those technologies which thanks to the use of a diy plastic injection molding machine.

These injection molding machines are perfect for use at home. A guide to choosing the right material for plastic injection molding. Injection Molding Urethane Casting CNC Machining Vacuum Casting Sheet Metal Machine Tooling Industries.

Secrets of Building a Plastic Injection Molding Machine by Vincent R. What are the components in making bricks out of plastics materials needed 2. Are all kinds of plasticsokay in making bricks 3.

Now that you have your epoxy molds ready you can finally set them up on an injection molding machine before pouring in molten plastic. It is very easy to machine is readily available and has a low melting temperature making it particularly simple to use in injection molding manufacturing processes or 3D printing. It allows the production of components in polymeric material.

Designed for end-to-end user independence yet we are here to help. Steel flat bar stock. The types of molding have.

Or let usHelp You. In order to achieve the 175 mm thickness after cooling I determined that the appropriate size hole to drill was around 135 mm which accounts for the expansion of the filament as it extrudes out of the nozzleIf you own a drill press use it to drill this hole. It is used predominantly as a fiber known by the trade name polyester and for bottling or packaging.

SZOMK china electric enclosures suppliersplastic enclosure in chinaextruded aluminum enclosuremetal enclosures manufacturers. They outperform traditional materials such as steel aluminum wood or plastic and enable the fabrication of high-performance lightweight products. May 8 2015 600 am PDT.

The Model 150A is a relatively cheaper. Though it is optional using this method the straighter the hole the easier it is to control the filament after it exits the nozzle. Supports a wide range of manufacturing processes materials and inspection scenarios from automotive parts and plastic injection molding to metal soldering and packaging.

Based on inputs from sensors the ECM controlled the injection volume and timing of each type of fuel injector according to engine load and engine speed to optimise the fuelair mixture for engine. There are quite a few injection molding machines available online which are fit for a DIY or domestic work environment. AK-B-14 plastic waterproof box.

Read on to see the best DIY and desktop injection molding machines. Find expert advice along with How To videos and articles including instructions on how to make cook grow or do almost anything. Difficult to cut or machine.

0217 2022 Air Purifier. News stories speeches letters and notices. In this guide learn the basics of manufacturing carbon fiber parts including the different methods and how you can use 3D printing to lower costs and save time.

The four valves per cylinder two intake and two exhaust were actuated by roller rocker arms which had built-in needle bearings that reduced the friction that occurred between the camshafts and the roller rocker arms. Automation Components for industrial applications. Get dozens of projects in every issue covering DIY electronics 3D printing craft and more.

Use cases applications. Over the years and with the development of increasingly advanced technologies. MISUMI offers free CAD downloads prompt lead times competitive pricing and no minimum order quantity.

PET is the most widely produced plastic in the world. The FA20E and FA20F engines have a cast aluminium alloy cylinder head with chain-driven double overhead camshafts per cylinder bank.

Youtube Plastic Injection Molding Injection Machine Injection Moulding

Make Your Own Injection Molding Machine Make Plastic Injection Molding Diy Molding Epoxy Resin Crafts

Home Injection Molding Diy Molding Injection Moulding Plastic Injection Molding

Plastic Injection Moulding Machine Model 4 Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Diy Injection Molding Plastic Injection Molding Plastic Injection Injections

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Bestseller Books Online Build A Plastic Injection Molding Attachment For A Drill Press Vincent R Ginger Plastic Injection Molding Plastic Injection Injections

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Injection Moulding Mould Design

Homemade Plastic Injection Molding Machine Plastic Injection Plastic Injection Moulding Machine Plastic Injection Molding

Microplast Hot End Youtube Plastic Injection Molding Plastic Design Plastic Injection Moulding Machine

1 300 Hobby Business Plastic Injection Molding Machine Molder Press Free Mold Ebay Refurbi Plastic Injection Moulding Machine Plastic Moulding Diy Molding

Hand Injection Molding Machine For Plastic 0 400 C Home Appliances Machine Molding

Desktop Injection Molding Machine Injection Machine Plastic Moulding Diy Molding

Home Made Injection Machine Injection Machine Injections Injection Moulding

Diy Injection Molding Machine Plastic Injection Moulding Machine Plastic Injection Molding Plastic Moulding

Injection Molding Machine By Scorch Homemade Plastic Injection Molding Machin Plastic Injection Moulding Machine Plastic Injection Molding Plastic Injection

Pin By Arbi Oussama On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Plastic Moulding

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

Plastic Injection Molding Lns Technologies Plastic Injection Molding Machines A Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

0 Response to "diy plastic injection molding machine"

Post a Comment